Stainless Steel Grade

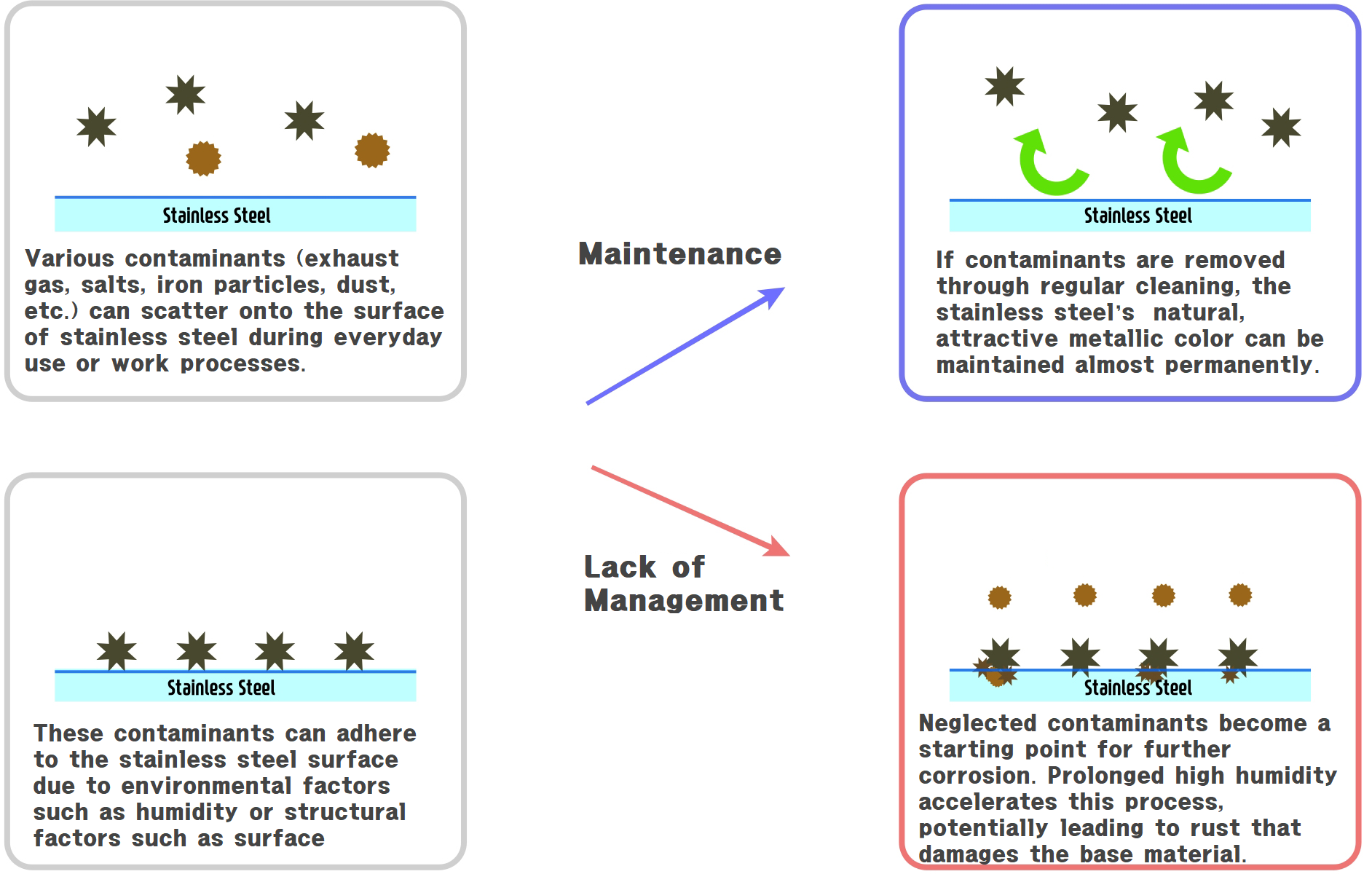

Stainless steel is often misunderstood as a perfect metal material that does not rust or corrode. To be precise, stainless steel is a metal material that requires almost no corrosion in general environments and is very easy to maintain, unlike other metal materials, without separate surface treatment.

However, many people have misconceptions about the use and application of stainless steel due to excessive trust, which becomes a source of disputes between suppliers and users. In particular, corrosion appears as local or unexpected phenomena due to the complex interaction of various factors, creating negative situations for stainless steel. It is important to know and practice handling methods to use stainless steel stably for a long time. (Korea Iron & Steel Association)

When the passive film* of the stainless surface is damaged and regeneration is hindered, rust occurs. Substances that destroy the passive film and hinder regeneration are mainly chloride ions and sulfur oxides. Chloride ions include salt, bleach, deicing agents, seawater, etc., and sulfur oxides include combustion exhaust gases from automobile factories, incineration smoke, and oil, which adhere to the stainless steel surface and cause discoloration, blue rust, cracks, and other corrosion.

Also, in factory areas, when processing using the same equipment as steel products, iron-based heterogeneous metal particles often attach to the stainless surface and contaminate it. Galvanic corrosion occurs due to the standard electrode potential difference between the two metals on the surface, causing rust on the foreign matter, and this foreign matter affects the stainless steel itself in the long term, so periodic cleaning is necessary.

1. Various equipment should avoid sharp angles and be made round as much as possible to avoid accumulation of foreign matter.

2. When installing tanks and other equipment, sufficient consideration should be given to facilitate regular maintenance, management, and cleaning, and install accessible windows. In particular, low water tanks, hot water tanks, etc. are vulnerable to corrosion in the upper part and the area where the water level changes, so making the tank shape full can minimize corrosion occurrence.

3. Install ventilation holes in low water tanks to prevent chlorine gas from accumulating inside the tank, and adopt a spray method when supplying water so that the upper part and water level change part inside the tank are cleaned.

4. The arrangement of pipes should clearly distinguish between high and low so that the flow of fluid inside is not hindered, and U-shaped pipes should be avoided as much as possible. Install vent valves in U-bends to drain internal liquids when not in operation.

5. Design welded parts to be minimally exposed to harmful environments, and consider brazing or soldering as alternative fastening methods.

6. If frequent cleaning is required or large particle adhesion is a concern, choose easy-to-clean surfaces like HL and #4.

Taking 304 grade stainless steel as an example, which does not have magnetism in its general state, it is in a state where the work-induced martensite generated during the rolling process is almost removed through solution heat treatment during steelmaking. When this material is subjected to slitting/shearing or cold forming, some of the austenite transforms into work-induced martensite, and the generated martensite causes weak magnetism.

The amount of martensite generation increases as the deformation amount of stainless steel increases, so it can be seen that it occurs intensively in places where thickness changes are large after forming (places with large deformation). Martensite phase has the characteristic of being magnetic and strong, unlike austenite phase. In fact, this work hardening is sometimes used in the production of high-hardness products (products that are not heat-treated after cold rolling). (Korea Iron & Steel Association)

The components listed in the test certificate of stainless steel products are ladle analysis values obtained by analyzing samples taken from molten steel with confirmed components before casting. Therefore, stainless steel from the same ladle (Heat No. / Charge No.) guarantees the same components regardless of the final product specifications and surface.

However, there are cases where the deviation of major elements becomes a problem. When there is a difference between the value shown in the certificate and the actual product analysis value, the component tolerance is specified in each specification book for reference. (ASTM A480 A1.1 Product analysis tolerance)

300 series is Cr-Ni series austenitic, and 400 series is Cr series ferritic, showing differences in weldability due to physical properties and structural differences.

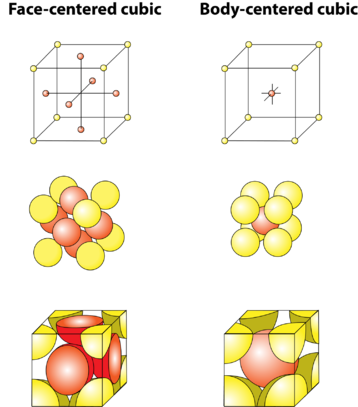

300 series has a face-centered cubic structure (FCC) with high solubility of carbon, nitrogen, etc., while 400 series has a body-centered cubic structure (BCC) with low solubility of carbon and nitrogen. When the weld area is exposed/contaminated by carbon or nitrogen, weld cracking or toughness degradation occurs*. Also, the melting point is more than 50°C higher than 300 series, and thermal conductivity is also higher than 300 series, requiring a lot of heat for melting and accumulation of welding heat is important.

FCC (Face-Centered Cubic: face-centered cubic lattice) and BCC (Body-Centered Cubic: body-centered cubic lattice) structure diagrams

| Category | Handling Guidelines |

|---|---|

| Storage | Care should be taken to prevent rust from occurring on the surface due to accumulation of moisture, dust, oil lubricants, dust, etc. |

| Transportation | Use supports to prevent surface scratches and use stainless steel dedicated equipment |

| Cutting and Pressing | The gap between dies and blades must be accurate to prevent burrs or work hardening and be clean |

| Bending Process | Surface grinding is necessary when bending welded parts to prevent processing cracks |

| Drawing | Use lubricants with pressure resistance or heat resistance as friction and surface damage occur during deep processing After forming, cleanly remove oil remaining on the surface |

| Welding | Completely remove rust, oil, moisture, paint, etc. that adversely affect welding and work After welding, perform grinding and acid cleaning to prevent local corrosion or strength reduction |

| Construction Part | Keep in mind the life of protective film and clean the surface when removing film after construction Be careful about contact with cleaning agents for tiles and stone with strong corrosiveness, and clean immediately if contacted Be careful about exposure to cement, dust, etc. during construction at construction sites, and clean with neutral detergent and water after completion |