Product

Sanyo Special Steel is one of the world's oldest special steel bar manufacturers, founded in 1935. With approximately 90 years of history, we take pride in our established know-how and the guaranteed quality that comes from it.

Sanyo Special Steel's high quality can also be confirmed through its production process.

To explain a bit more about the production process of Sanyo Special Steel stainless steel bars, it consists of an electric furnace - converter - secondary refining - continuous casting line steelmaking process.

Quality management begins from the moment molten steel is tapped. By not tilting the molten steel in all processes, the inclusion of upper slag is prevented. Since there are no sections in the process that come into contact with oxygen, unnecessary oxide generation can also be minimized.

Through converter refining and secondary refining processes, non-metallic inclusion generation is also significantly reduced. In addition, the secondary refining process uses an RH (Ruhrstahl Heraeus) Degasser, which specializes in removing unnecessary gases from molten steel. Therefore, the possibility of hydrogen embrittlement and bubble defects is significantly reduced. The possibility of defects caused by "inclusions" or blow holes, commonly mentioned, is significantly reduced through the above process.

When you visit Sanyo Special Steel's factory, you can see promotional materials celebrating "Tundish Nozzle 100 Charge Continuous Casting Achievement Guinness Book Entry." A tundish is used to introduce molten steel into the line connecting the secondary refining furnace to the casting mold, and the fact that this tundish nozzle (SEN, Submerged Entry Nozzle) was used 100 times to make it into the Guinness Book means that. Molten steel with non-metallic inclusions that are not properly removed causes clogging of the tundish nozzle, but Sanyo Special Steel was able to set such a record because it was already specialized in producing high-purity steel in the refining process.

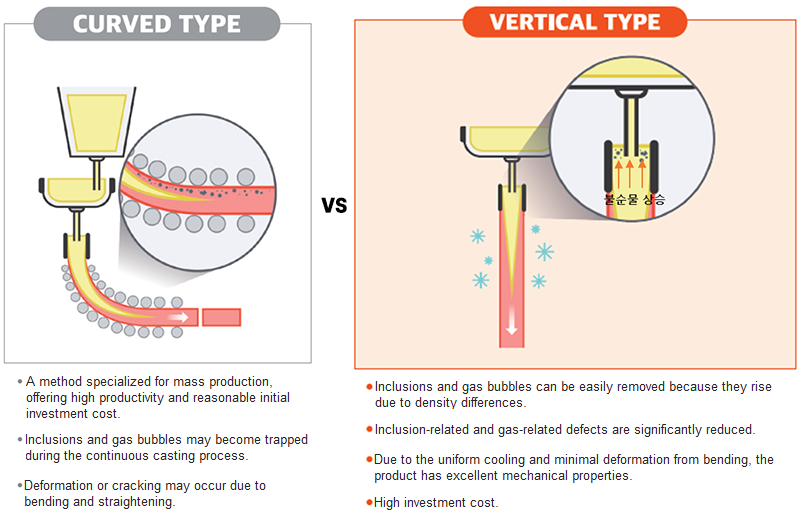

Another major advantage of Sanyo Special Steel products is vertical continuous casting production. It consists of a total 41m casting line, which is a method that is rarely used today due to high equipment investment costs.

The biggest advantage of vertical casting is that it can produce high-purity blooms. This is because in the casting process, molten steel flows in the direction of gravity, so non-metallic inclusions or unnecessary bubbles in the molten steel are separated and rise due to density differences. Therefore, high-purity blooms can be produced by removing the parts containing impurities. High-purity blooms undergo subsequent processes such as rolling and achieve high quality through thorough quality inspection processes.

Sanyo Special Steel products are produced through the most suitable equipment for high-purity steel products, so you can expect high quality compared to other imported materials.

Sanyo Special Steel Stainless Steel Bar TP 304 Forged Product

Hwangkum Steel and Technology has contracted as the first official sales company for Sanyo Special Steel's stainless steel round bars in Korea, and we will do our best to supply excellent products competitively in the future.